ENCODE connects design and construction with Speckle

Improved communication

Across all four projects, Speckle enabled ENCODE to fundamentally improve how they worked. Communication became faster and clearer, allowing teams to stay aligned and responsive.

Better stakeholder alignment

Stakeholders—ranging from designers and engineers to fabricators and contractors—were better aligned thanks to a shared, real-time source of truth.

Fewer errors and delays

By replacing manual updates with real-time data sharing, Speckle significantly reduced fabrication errors and on-site delays.

Accurate and flexible workflows

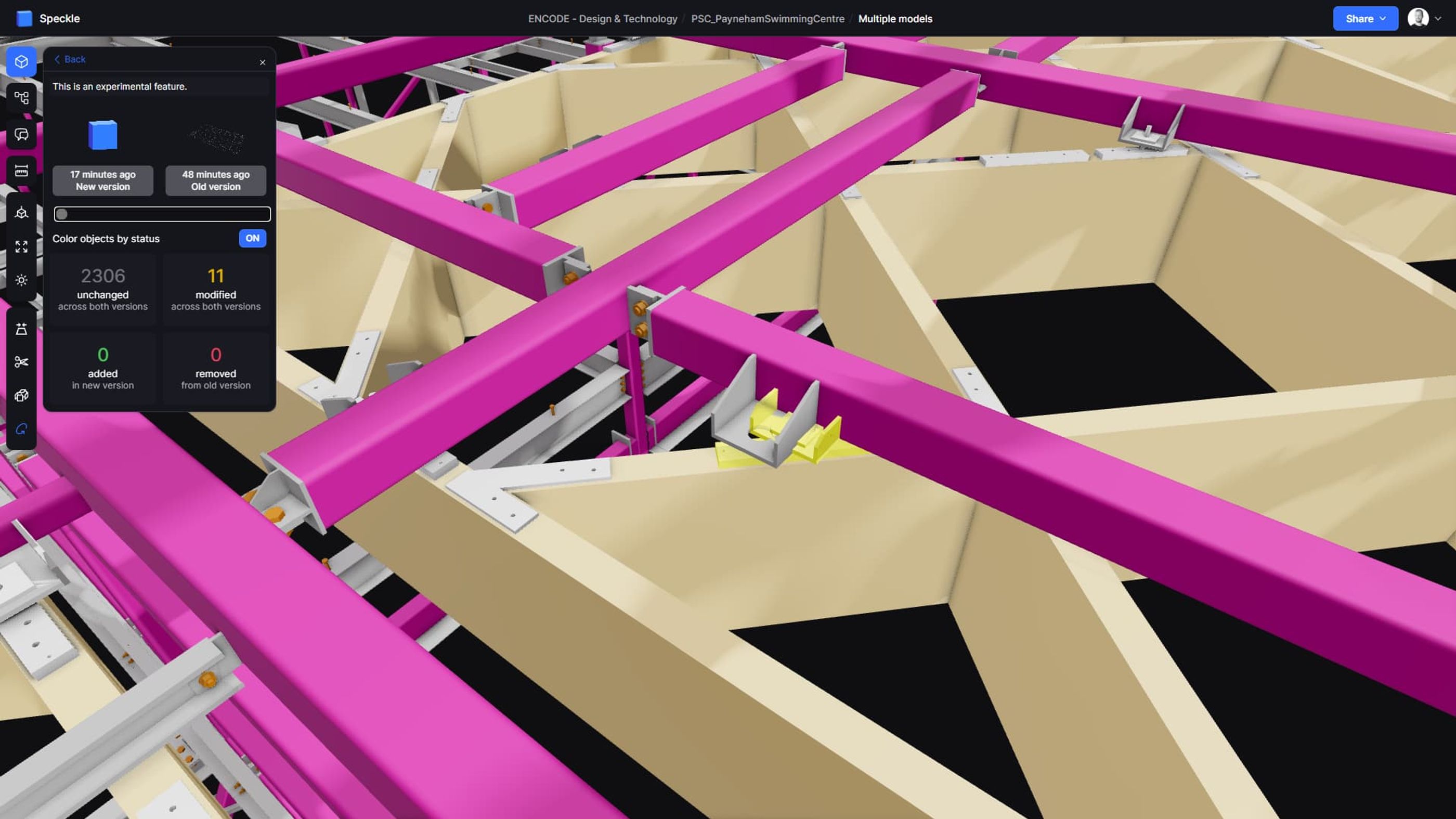

Speckle’s versioning capabilities helped maintain accuracy throughout each stage. Teams could adapt designs quickly while ensuring precision and consistency.

There's a better way to work together in 3D.

Company

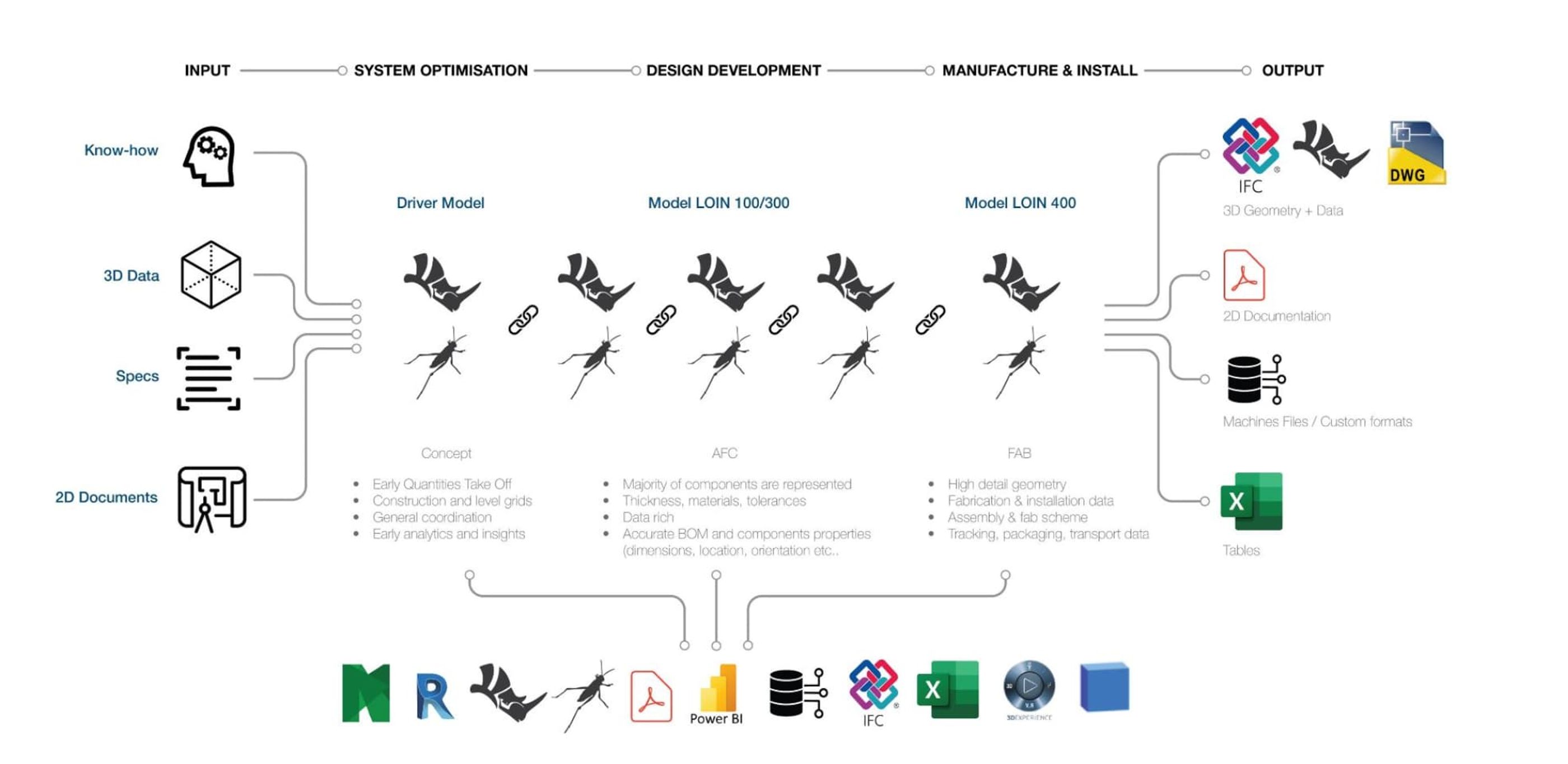

Founded by Federico Borello and Massimiliano Manno, ENCODE bridges the gap between digital prototyping, computational design, and real-world construction.

They aim to integrate design, technological insight, and construction expertise, driving innovation in the architectural and construction sectors.

By combining Virtual Design Construction (VDC) and Product Lifecycle Management (PLM), ENCODE enhances every stage of the architectural design process—from initial concepts to manufacturing and on-site installation.

Operating vendor-agnostic, they work seamlessly with geometry and data, free from the constraints of siloed software, making Speckle an essential part of their workflow.

Challenge

In Sydney, ENCODE worked on a grid shell structure for the Master Build Association, which demanded tight coordination between timber and steel suppliers, and KANE Construction. The team needed to manage a vast amount of design and fabrication data while preparing a prefabricated structure to be built in Europe and shipped across the world.

In the three-year-long Metro Martin Place North Tower project, the challenge was to design and deliver modular stair systems and edge boards while onboarding consultants and stakeholders across phases. Real-time access to critical production data was essential to keep the project moving.

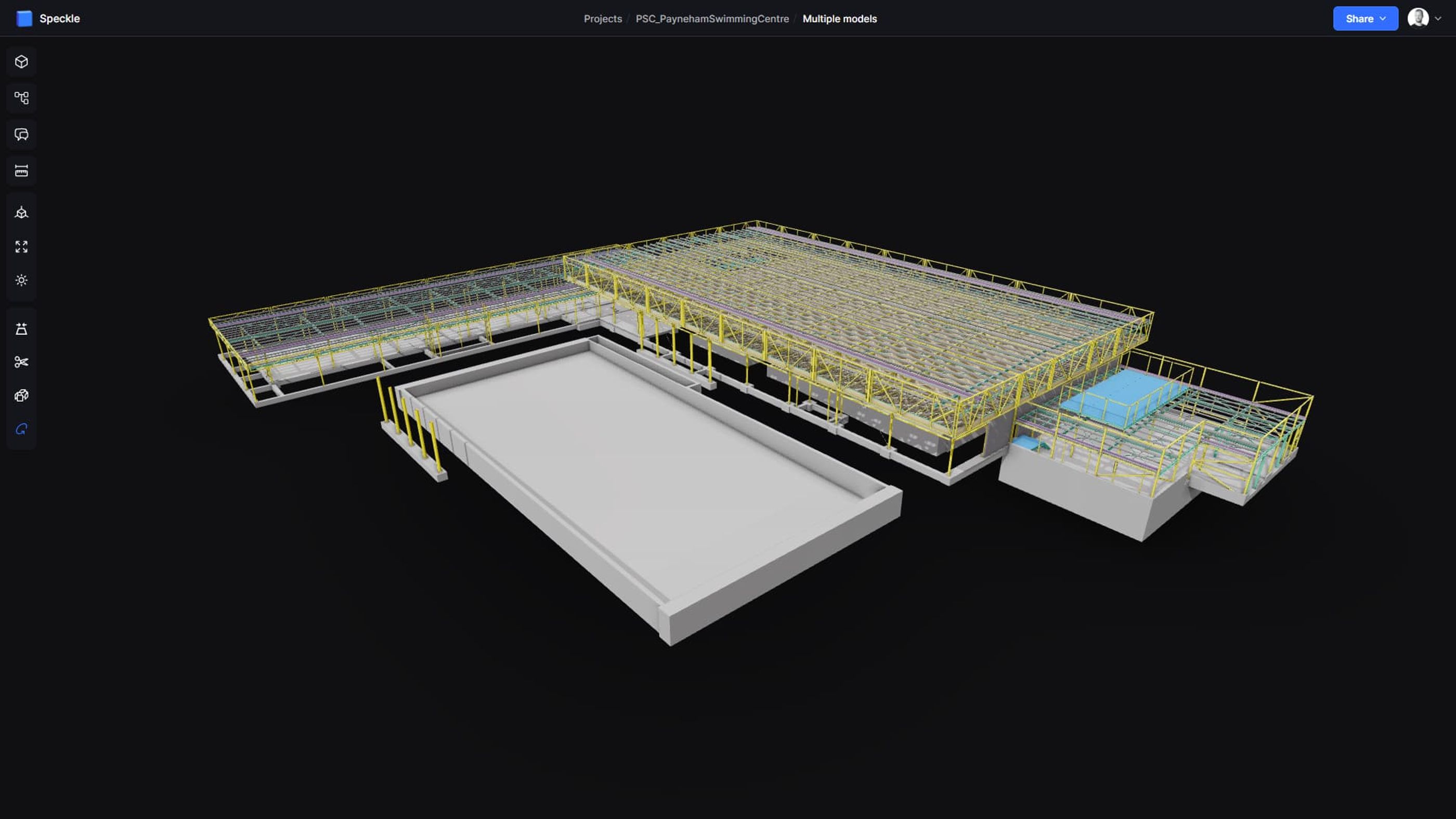

Meanwhile, Browne Park Stadium shifted from a mass timber to a steel construction approach midway through, emphasizing the need for flexible communication and fast onboarding of new engineers and suppliers. Similarly, the Paynhame Swimming Centre, which involved a modular timber roof system for an Olympic-sized pool, required extreme precision during prefabrication and on-site installation.

In all cases, ENCODE needed a solution that could bridge design, production, and construction—with collaboration and version control at its core.

Solution

To meet these demands, ENCODE turned to Speckle. It served as a centralized repository and single source of truth across all four projects, enabling smooth communication between geographically distributed teams, fabricators, and stakeholders.

Speckle’s ability to integrate with industry-standard tools such as Rhino 3D and Power BI further empowered the team to work effortlessly from concept to delivery. By consolidating project assets in one place—drawings, dashboards, assembly info—ENCODE was able to reduce manual coordination and focus on high-value design and execution.

How they did it

In the Master Build Association project, ENCODE used Speckle to unify all project data in a central repository. This enabled clear communication of updates to manufacturers and contractors, significantly reducing errors and delays. With the prefabricated structure being built in Europe and shipped to Australia, Speckle allowed the team to design shipping containers early in the process—minimizing transport risk and ensuring efficient assembly on site. During installation, the Speckle 3D model became the team’s primary communication tool, facilitating real-time collaboration among all stakeholders.

For the Metro Martin Place North Tower, Federico’s team used Speckle to visualise project data and onboard stakeholders smoothly. The Power BI connector was pivotal, linking metadata with fabricators to ensure up-to-date access to critical production information. Combining Rhino 3D with Speckle, the team maintained design fidelity while efficiently communicating updates.

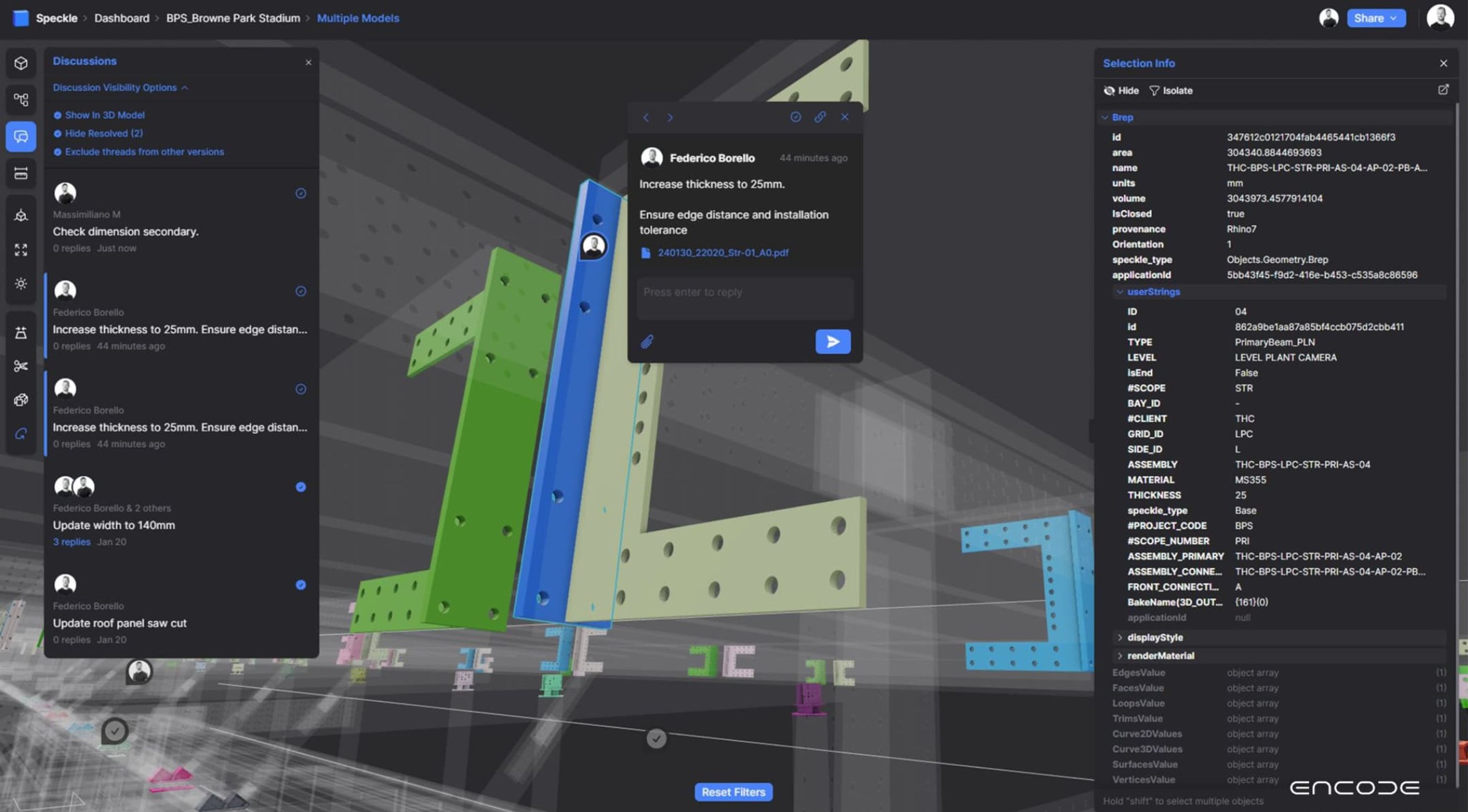

At Browne Park Stadium, when the project shifted to steel, Federico and Max used Speckle to rapidly bring new engineers and suppliers up to speed. The commenting feature within the Speckle 3D viewer became key in streamlining feedback and iterating on design adjustments as the project progressed.

In the Paynhame Swimming Centre, Speckle’s versioning capabilities ensured that any issues during the design and prefabrication phases were addressed in real-time. This maintained the precision and quality required for smooth on-site installation of the modular timber roof system.